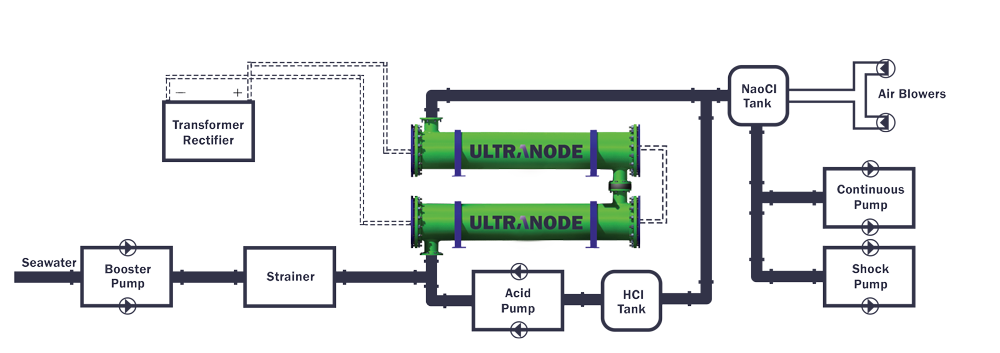

ULSeawater™ systems are, as the name implies, applicable only in coastal areas and offshores. These systems are applied to control biological activity in all forms of circulating cooling systems where seawater is the cooling media such as power stations, refinery complexes, fertilizer plants, desalination plants, etc. Many of these applications are remote hence difficult to utilize most of the disinfection methods, making seawater electrochlorination system very cost-effective.

ULSeawater™ utilizes seawater feed with high flow rates to help control cathode fouling from the naturally occurring magnesium and calcium in seawater. As a result, the product concentration of sodium hypochlorite is low (max. 2500 ppm) and operating current efficiency is high, as the power consumption for ULSeawater™ electrolyzers is <4.4 kWh/kgCl2. Due to the seawater providing a “free” source of salt, these systems contain smaller equipment of less variety than brine electrolysis systems.