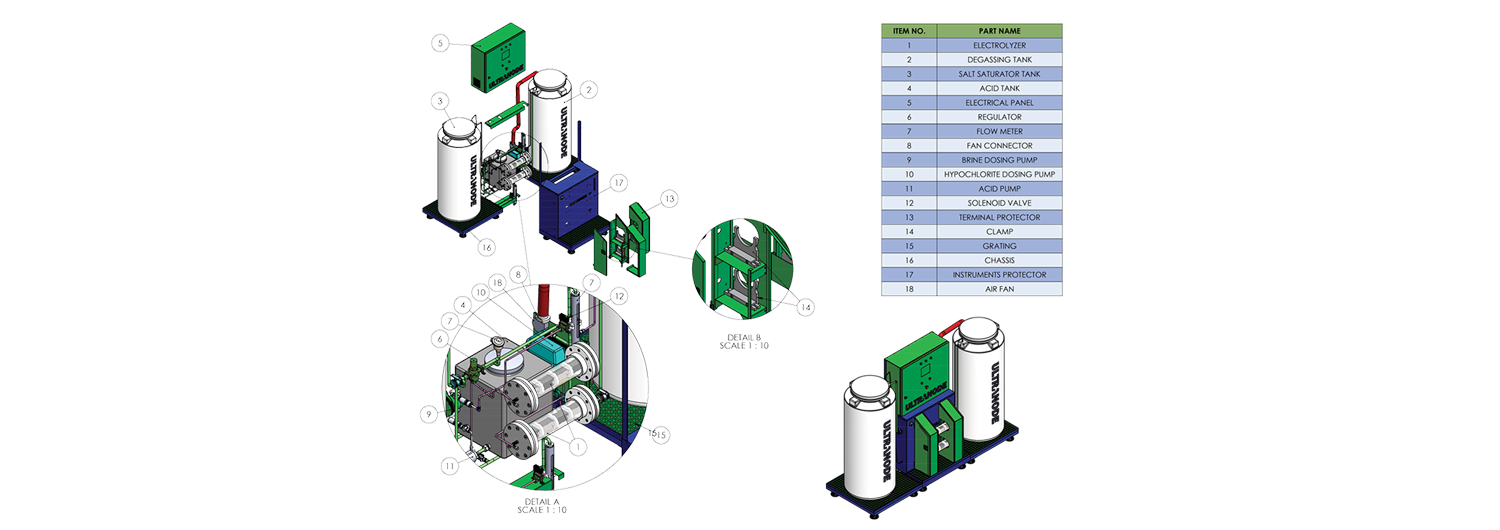

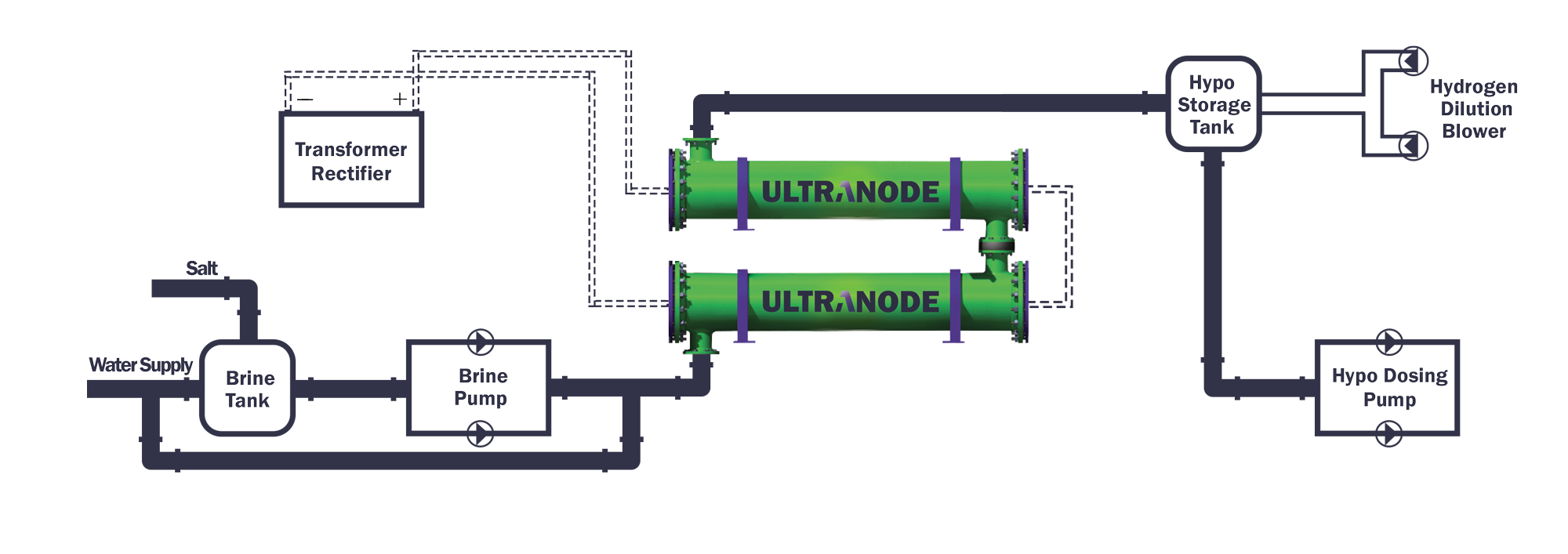

ULBrine™ systems are designed specifically for operation on artificial brine sources and can be used for any application requiring hypochlorite as the disinfectant, where seawater is not accessible or they are to be used for drinking water chlorination. These systems are installed inland and are designed to provide substantial quantities of sodium hypochlorite (in the storage tank) to assure that disinfection capacity is always available to the end-user.

ULBrine™ systems can produce sodium hypochlorite up to 8000 ppm concentration. These systems are modular in construction and can be designed according to the customer’s requirements and limitations.

ULSeawater™ utilizes seawater feed with high flow rates to help control cathode fouling from the naturally occurring magnesium and calcium in seawater. As a result, the product concentration of sodium hypochlorite is low (max. 2500 ppm) and operating current efficiency is high, as the power consumption for ULSeawater™ electrolyzers is <4.4 kWh/kgCl2. Due to the seawater providing a “free” source of salt, these systems contain smaller equipment of less variety than brine electrolysis systems.