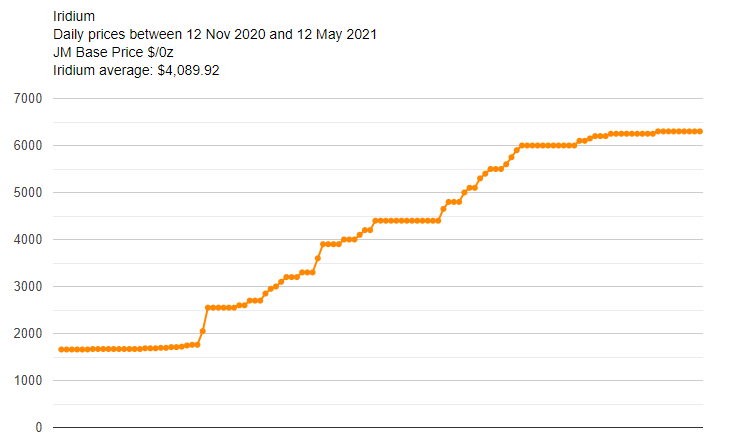

Iridium is a by-product of platinum extraction and it is produced by a small number of producers in which South Africa is the main producer of Iridium (81% of global iridium mine supply). The price of this precious metal has soared drastically from the beginning of the year 2021 and now only 31 grams of it, would cost a small amount of fortune about $6,000 which has become three folded within 7 months.

Volatility is largely due to the decline in the platinum market and as a result, the scarcity of iridium supply, mine technical issues as well as covid19 outbreak caused severe disruption in S African supply.

Due to its extreme hardness, very high melting point, temperature resistance, and resistant to corrosion characteristics, it is well suited in several industrial applications such as Electronics and telecommunications Industries in 5G technology – OLED Electronics account for 31% of total iridium demand, Automotive industries in high-performance spark plugs account for 13%, medical devices, and, Electrochemical industries in iridium-coated titanium electrodes for water disinfection purposes no matter the water is used In an industrial application or not, account for 26% of the total demand in 2020.

In Ultranode, Iridium, Tantalum, Rethenuim are used as mixed metal oxide (MMO). This special Nanotechnology coating is performed on the titanium electrodes /substrate (Anode) to strengthen the anode to have much resistance against corrosion, to get an appropriate performance, increase the efficiency, decrease the electricity consumption and lengthen the lifetime of Electrochlorinator. Titanium electrodes will be arranged and placed with a particular design and order, in a special format, which then constitutes the electrolyzer cells.

In more detail, the electro chlorination process is when Direct Current passes through the titanium electrodes to the electrolyte (salty water), the chlorides will disassociate to form the Hypochlorite which is the great disinfectant. Application of electrochlorination are in Refineries and Petrochemical Industries, Desalination Plants, Coastal Installations and Offshore Treatment Systems, Drinking Water Plants, and especially Ballast Water Treatment Systems in Marine Vessels to treat ballast water before it is discharged into the sea as a mandatory step (2019 accord reached under the auspices of the UN’s IMO).