Seawater Desalination

Water droughts have led countries to start thinking and also implementing water desalination plants. At the moment, several countries in the Gulf provide a big chunk of their potable water from desalination. However, before it begins, we must get rid of Microorganisms. The Sea Water needs to be chlorinated to prohibit the growth of blue mussels and algae through the desalination steps. Moreover, you must have a residual chlorine in water before pumping the drinkable water. This residual chlorine keeps the water free from pathogenic microorganisms that may lead to severe disease. Therefore, disinfection is done to avoid bio-fouling and disease, but how?

We need only Seawater, that is assumed to be in hand, and electricity. Electrochlorination generates Sodium Hypochlorite, on-site and on-need, without the need for any additives or particular treatments. When the electricity current passes through the seawater, the electrolysis of saltwater happens, consequently producing sodium hypochlorite and hydrogen gas (H2). The solution is going to be moved into a reserve tank. The hydrogen gas is separated considering its low gravity. The reaction could be stated as:

NaCl + H2O + ENERGY →NaOCl + H2

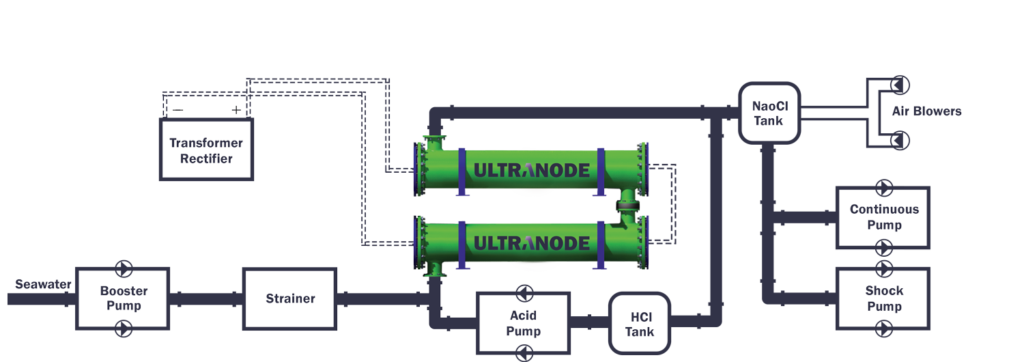

A schematic of the process is been presented below. This plan shows a complete process with all the accessories including Booster Pump, rectifiers, Cells, Acid Tank and Pumps and Dosing Pumps, etc.

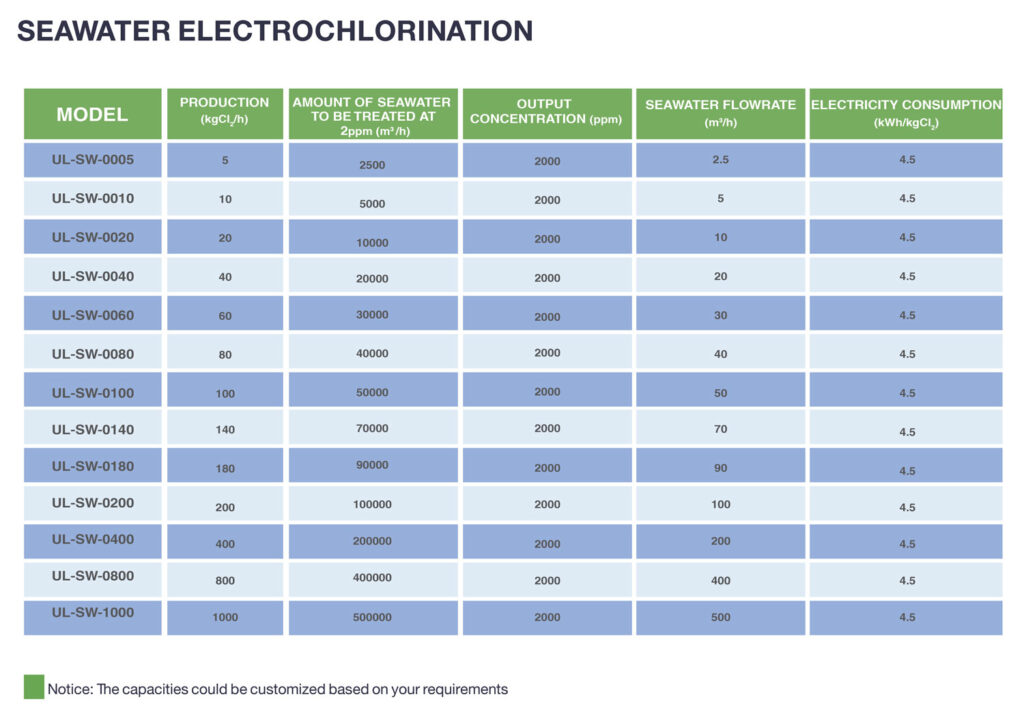

ULTRANODE supplies a wide range of Models for various capacity of Electrochlorination plants.